Inventories and Stock In/Out Management

|

Inventory Management is to manage physical goods. They can be produced products, work-in-progress, assemblies, or purchased raw materials, parts, etc. Raw material, work-in-progress, parts, assemblies are usually used to produce products. Parts and assemblies can be used to support operations, such as maintenance and repairing. They can also be used for customer product services, such as post-sales finished goods services and spare parts sales. LogixPath Inventory Management subsystem helps businesses to efficiently track inventory stock locations and quantities, and their movements, such as moving stocks into an inventory or removing them from an inventory. It provides tools, such as barcode or QR code scanning, to quickly search stocks by part number, stock code, barcode, etc. |

|

Feature Highlights:

|

Functionality Highlights

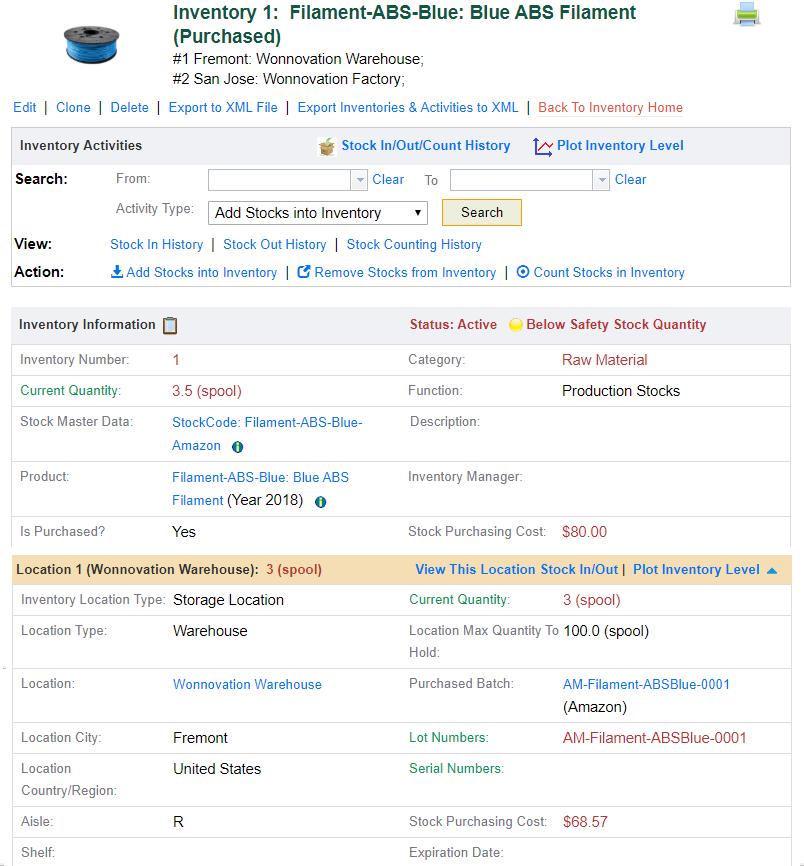

Define Inventories and CharacteristicsInventory: Inventories are actual physical stocks stored in one or multiple locations. Their functionalities can be:

Stock Master Data: One product can have multiple inventories for the different purpose, such as parts for producing new products or parts for repairing existing products. These inventories may have different Inventory Level Thresholds Parameters. LogixPath software uses Stock Master Data concept to allow users to define different purposed inventories. Stock Master Data defines the characteristics of an inventory, such as Product, physical good dimension/size, Inventory Level Thresholds Parameters, Shelf Life Span and expiration warning level settings. An inventory associates to one Stock Master Data to define its characteristics. Multiple Inventory Locations: Each inventory can have one or more locations. The inventory move in/out, counting, and stock level plotting supports multi-location inventory. |

Stock TrackingThe software tracks inventory stock locations and quantities. It provides tools to quickly search stocks by part number, stock code, barcode, etc. For Food, Bio-Chemical, and Pharmaceutical industries, Stock Expiration Date management is vital. LogixPath software lets users to record stock expiration dates of the Purchased Batches, Produced Batches, and Inventory stocks. It provides search tools to easily find stocks which are expired or will be expired soon. Here are some capability highlights:

|

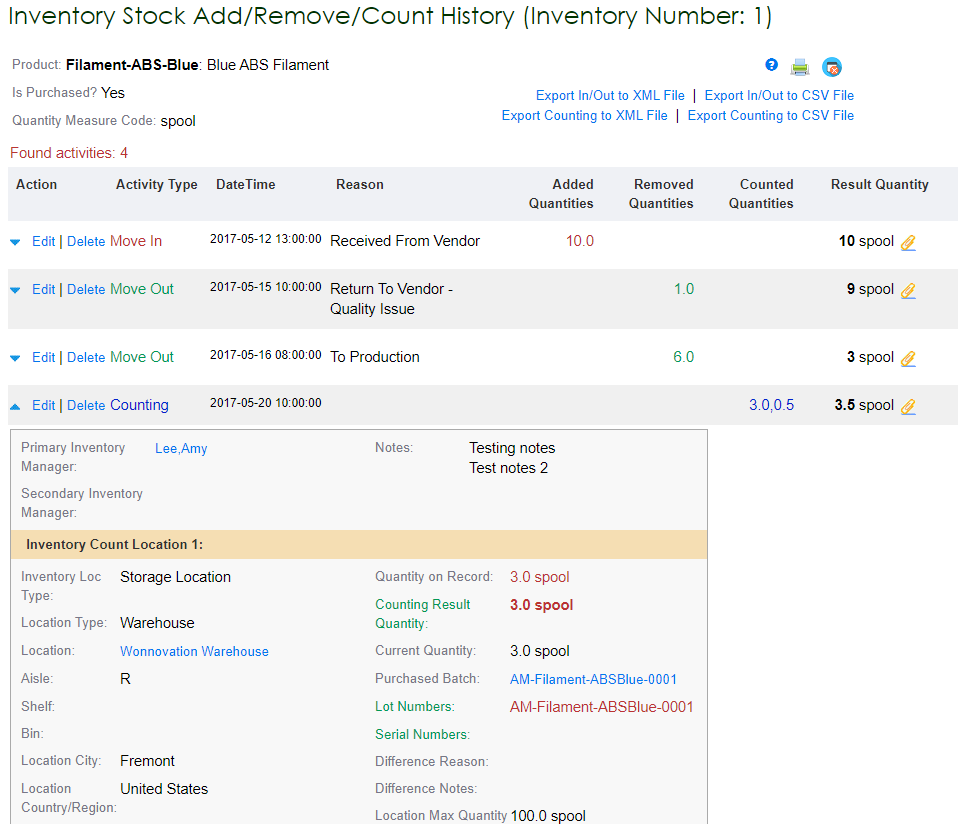

Inventory Activities TrackingFor each inventory, you can record and track stock move in and out activities and perform the stock cycle counting. The system displays all these activities according to timeline. For each activity, it displays stock in/out quantity and the result stock quantity balance in the inventory. The system also plot the inventory level along the timeline based on these activities. Here are some capability highlights::

|

Inventory levelSystem calculates current inventory level based on the Inventory In/Out/Count activities. Each inventory counting resets the inventory level to that quantity. System dynamically calculates and plots inventory level over timeline diagram for a particular inventory. |

Sample Inventory Screen

|

Inventory Management

|

|

Inventory Move Activities and Cycle Counting

|