Sales Order to Production Lifecycle Management

|

LogixPath Operations Management software helps businesses to follow through the Sales Order To Fulfillment lifecycle to ensure on schedule and cost effective product/service creations and deliveries. |

Sales To Production Primary Business Elements

|

Functionality Highlights

Cost and Delivery Date EstimationFor any order with heavy customization or configuration, large order quantity, or Engineer-to-order, the cost and delivery date estimation becomes crucial. Usually management needs to make the Make or Buy decision based on the cost and lead time. "Make or buy" can be in the entire product level or sub-assemblies or components level. Sometimes engineers are able to provide alternatives parts, production process adjustments, or even make product design adjustments to meet the cost and delivery dates requirements. LogixPath software provides various tools to help businesses to make these decisions more objectively. The BOM (Bill-of-Material) module enables engineers to clone to generate multiple similar BOMs, make adjustments to cloned BOMs, view the constituent components costs and lead time, and compare these BOMs side-by-side to view their differences. The Production Process Definition module enables production managers to generate multiple similar production processes with variant material or parts, labors, equipment needed. System will automatically calculate total costs and time duration at individual process step task level and the overall production process level. The Resource Demand and Capacity Analysis engine can check and analyze the current availabilities and demands for the required resources (material/parts, labors, and equipment) based on the BOM or Production Process definitions, and current job orders in the pipeline and on-going production runs. After these "what-if analysis", management can make the right decisions on Make vs. Buy, and engineering design or product production process choices. And then provide customers more accurate prices and delivery dates. This capability helps Job Shops, Engineer-To-Order, and project based customer orders significantly, it enables businesses to optimize the balance among product features, time to delivery, and profitability. |

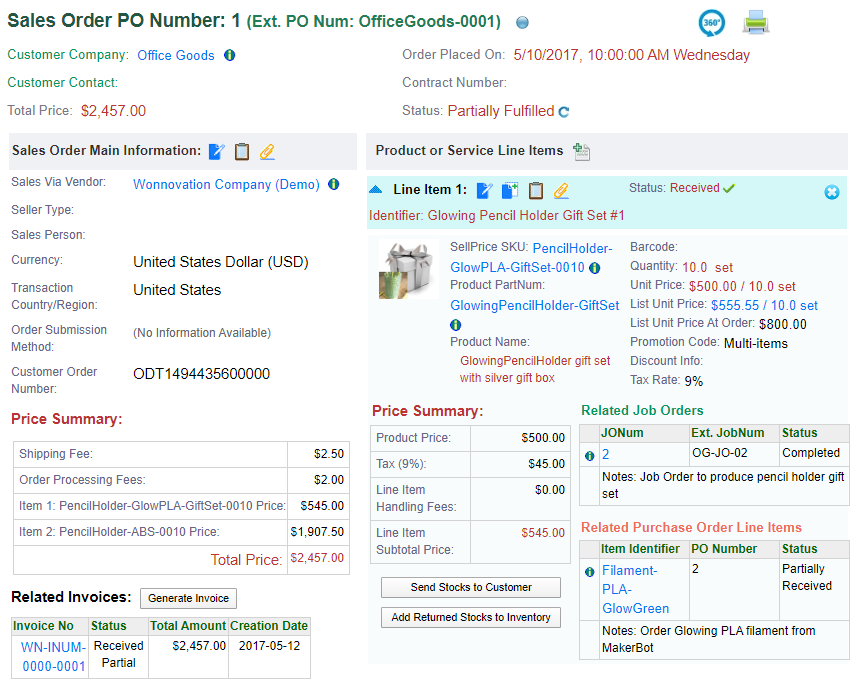

Integrated Operations Management From Sales Order To ProductionIn LogixPath system, business elements are tightly related to each other based on the product sales to product production and to delivery lifecycles. For example, a sales order line item may be related to multiple purchase order line items and multiple job orders. Often these relationships are many-to-many relationship, for example, one sales order line item can associate to multiple purchase order line items and one purchase order line item can be associated to multiple sales order line items. This integrated management helps businesses to efficiently follow through the entire process from sales to delivery to ensure on schedule and on budget deliveries. LPOM provides tools to create these relationships and view or traverse between related elements. Some of the relationship creation tools provide One-Click to create a related element, for example, you can create a corresponding Sales Invoice by clicking the button "Generate Invoice" in a Sales Order detail view; and create a Job Order for a line item by clicking the button "Generate Job Order" in the line item section of a Sales Order detail view. These element relationships enable LogixPath system to provide users overarching views to their operations and results. For example, a project detail view displays all associated sales orders, purchase orders, inventories, invoices, and payments with summaries of the total order values and payment amounts in each currency. |

Lot Number & Serial Number TraceThe business element relationships enable the system to trace the lifecycle of a given lot number or serial number, and identify the activities associated to it, such as the production run and produced batch which created this lot or item and the customer(s) this lot or item was sent to. |

Sample Sales Order Screen

|