|

|

| Summary: |

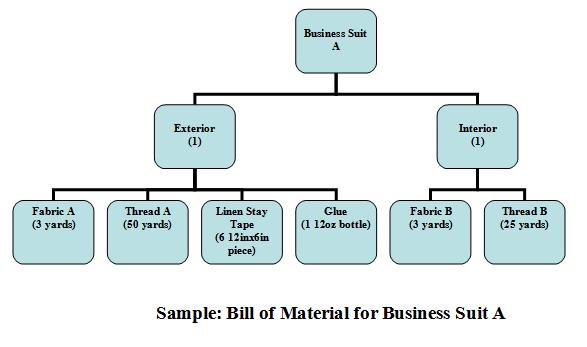

BOM represents relationships between a finished product and its constituent parts. |

| Detail: |

Bill of Material provides the relationship between a finished product, or end item, and its constituent parts, lower-level or child items. Child items include information of the name, quantity, and unit of measure of the component. It can include multiple levels of child items.

Variations of BOM:

- Manufacturing BOM: containing all the parts and assemblies required to build a complete and shippable product. It is also called "Material Specification" in the "Product Definition Model".

- Service BOM: containing all the parts, assemblies, drawings, and work procedures needed in the field for maintenance or service purposes.

- Engineering BOM: reflecting the product as designed by engineering, referred to as the "as-designed" bill of materials.

- Modular BOM: defining the component materials, documents, parts and engineering drawings needed to complete a sub-assembly.

- Configurable BOM: a form of bill of materials (BOM) used by industries that have multiple options and highly configurable products (e.g. telecom systems, data-center hardware (SANS, servers, etc.), personal computers, and automobiles).

Additional reference: Enterprise Bill of Materials

|

| Figures: |

|

| URL: |

http://enterprisebom.com

|

| Acronym: |

BOM |

|

|

| Subject: |

General |

|

|

|